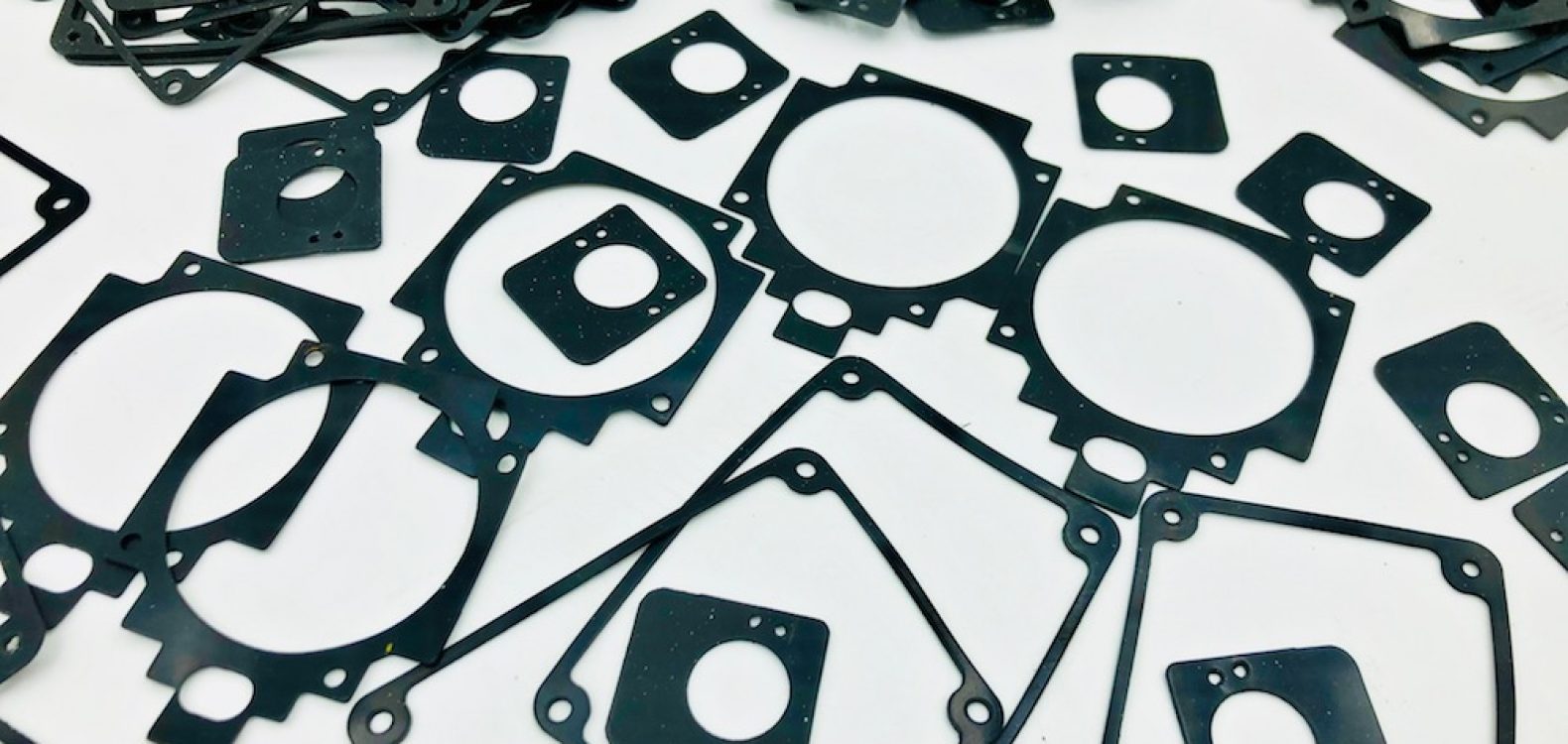

Seals and gaskets are essential components in various industrial and mechanical systems, serving a critical role in preventing the leakage of fluids and gases, as well as maintaining the integrity of a sealed environment. These components are used in a wide range of applications across industries such as automotive, aerospace, manufacturing, oil and gas, pharmaceuticals, and many others. In this extensive description, we will delve into the significance of seals and gaskets, their types, materials, manufacturing processes, and key considerations for their selection.

Significance of Seals and Gaskets:

Seals and gaskets play a vital role in ensuring the efficient operation and safety of machinery and equipment. Their primary purpose is to create a barrier that prevents the escape of liquids, gases, or contaminants from one part of a system to another. This is particularly important in systems where the leakage of fluids or gases could lead to operational failures, environmental hazards, or safety risks.

Types of Seals and Gaskets:

- O-Rings: O-rings are one of the most common types of seals, typically made of rubber or elastomeric materials. They are circular in shape and provide an effective seal when compressed between two mating surfaces.

- Gasket Sheets: Gasket sheets are flat materials, often composed of materials like cork, paper, rubber, or metal, that are cut to shape and placed between flanges or joints to create a seal.

- Mechanical Seals: Mechanical seals are typically used in rotating equipment such as pumps and compressors. They consist of two parts that rotate against each other, forming a dynamic seal.

- Lip Seals: Lip seals are commonly used in automotive applications, where they provide a seal between moving components, such as a rotating shaft and housing.

- Spiral Wound Gaskets: These gaskets are constructed by winding a metal strip and filler material into a spiral shape. They are widely used in high-pressure and high-temperature applications.

- Gland Packing: Gland packing, also known as packing or rope packing, is a traditional sealing method for valves and pumps. It consists of braided or twisted materials like PTFE, graphite, or asbestos.

Materials for Seals and Gaskets:

The choice of material for seals and gaskets depends on the specific application, including factors like temperature, pressure, chemical compatibility, and environmental conditions. Common materials include:

- Rubber (e.g., Nitrile, Neoprene, EPDM): Suitable for general-purpose sealing applications.

- Metal (e.g., Stainless Steel, Copper): Used in high-temperature and high-pressure environments.

- PTFE (Polytetrafluoroethylene): Known for its excellent chemical resistance.

- Compressed Non-Asbestos: A replacement for asbestos-based gaskets, offering good sealing properties without health risks.

- Graphite: Ideal for high-temperature and high-pressure applications.

Manufacturing Processes:

The manufacturing of seals and gaskets involves various processes, including cutting, molding, extrusion, and machining, depending on the material and design. Precision is crucial to ensure a proper seal, and modern manufacturing techniques use computer-controlled machinery for accuracy.

Key Considerations for Selection:

When selecting seals and gaskets for a specific application, engineers and designers must consider several critical factors:

- Operating Conditions: Temperature, pressure, and exposure to chemicals must be evaluated to choose the appropriate material and design.

- Conformity: The seal or gasket should conform well to the mating surfaces to prevent leaks.

- Durability: Depending on the expected lifespan of the system, the durability of the seal or gasket material is crucial.

- Cost: Balancing performance and cost is essential, as some specialized materials can be expensive.

- Environmental Regulations: Compliance with environmental and safety regulations is essential in many industries.

In conclusion, seals gaskets are fundamental components in countless industrial applications, ensuring the integrity and reliability of systems. Their design, material selection, and proper installation are critical to prevent leaks, reduce maintenance costs, and enhance overall system performance. Engineers and manufacturers continually innovate in this field to develop seals and gaskets that meet increasingly demanding requirements across various industries.