Industrial seals are critical components used in a wide range of industries to prevent the leakage or ingress of fluids, gases, or contaminants in mechanical systems and equipment. These seals play a vital role in maintaining the integrity, efficiency, and safety of industrial processes. The term “industrial seals” encompasses a broad category of sealing solutions, each designed for specific applications and operating conditions. This comprehensive description will cover the various types, functions, materials, and applications of industrial seals.

Types of Industrial Seals:

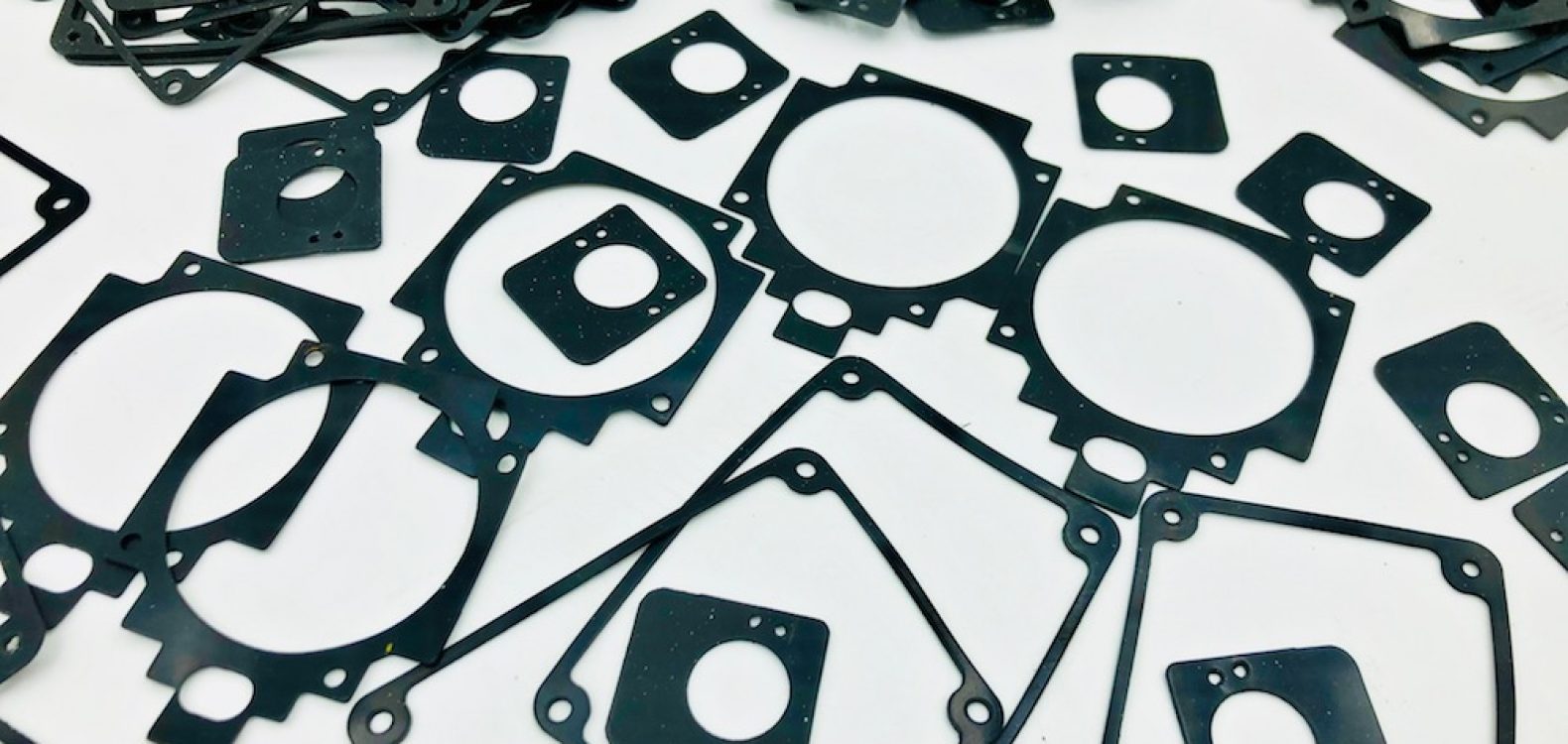

- Gasket Seals:

- Soft Gaskets: Made from materials like rubber, cork, or paper, soft gaskets are compressible and used in applications requiring low to moderate pressure sealing, such as automotive engines and pipeline flanges.

- Metal Gaskets: Metal gaskets, typically constructed from materials like stainless steel or graphite, are used in high-pressure and high-temperature environments, such as in the oil and gas industry or chemical processing.

- O-Rings:

- O-rings are circular seals, typically made of elastomers like nitrile, silicone, or Viton. They are used in a wide range of applications, from hydraulic systems in machinery to aerospace components.

- Mechanical Seals:

- Mechanical seals are used to prevent leakage in rotating equipment, such as pumps, compressors, and mixers. They consist of a rotating and stationary component, often with a sealing face made of materials like ceramic or carbon.

- Lip Seals:

- Lip seals, also known as oil seals, are used to prevent the leakage of lubricants or contaminants in rotating shafts, such as those in engines, gearboxes, and hydraulic systems.

- Hydraulic Seals:

- Hydraulic seals are designed for use in hydraulic and pneumatic systems to prevent fluid leakage and maintain the efficient operation of cylinders and other hydraulic components.

- Rotary Seals:

- Rotary seals, including radial shaft seals and rotary lip seals, are used in applications where rotating shafts need to be sealed, such as in gearboxes and wheel hubs.

- Pneumatic Seals:

- Pneumatic seals are employed in pneumatic systems to prevent air or gas leakage and maintain pressure. They are commonly found in applications like air compressors and pneumatic cylinders.

Functions and Characteristics:

- Leakage Prevention:

- The primary function of industrial seals is to create a barrier that prevents the escape of fluids or gases, whether it’s preventing oil leakage in an engine or gas leakage in a pipeline.

- Environmental Protection:

- Industrial seals protect machinery and equipment from environmental factors, such as dust, dirt, moisture, and chemicals, which can cause damage or corrosion.

- Pressure Management:

- Seals are engineered to withstand and manage various levels of pressure, whether it’s the high pressures found in hydraulic systems or the moderate pressures in HVAC systems.

- Temperature Resistance:

- Many industrial seals are designed to perform effectively across a wide range of temperatures, from extreme cold in cryogenic applications to high temperatures in industrial ovens and engines.

- Chemical Compatibility:

- Seals are made from materials that resist chemical attack, ensuring they remain functional and safe in aggressive chemical environments.

- Friction Reduction:

- Seals in rotating equipment help reduce friction, which not only enhances efficiency but also extends the lifespan of components.

- Vibration and Shock Absorption:

- Some seals are designed to absorb vibrations and shocks, improving the stability and reliability of equipment.

- Longevity and Reliability:

- Industrial seals are engineered for durability, with the goal of providing long service life and reducing maintenance and replacement costs.

Materials:

Industrial seals can be made from various materials, including but not limited to:

- Elastomers: Rubber-based materials like nitrile, silicone, and EPDM.

- Plastics: PTFE (Teflon), polyurethane, and various thermoplastics.

- Metals: Stainless steel, carbon steel, and various alloys.

- Ceramics: Often used in mechanical seals and high-temperature applications.

The choice of material depends on factors such as the application, operating conditions, and the specific properties required, such as chemical resistance, temperature tolerance, and compressibility.

Applications:

Industrial seals are used in a wide array of applications, including:

- Manufacturing and Machinery:

- In manufacturing equipment, industrial seals are essential for ensuring the proper functioning of conveyors, pumps, and hydraulic systems.

- Automotive:

- In automobiles, seals are used in engines, transmissions, brakes, and suspension systems.

- Aerospace:

- Aerospace applications require seals that can withstand extreme temperatures, pressures, and conditions.

- Oil and Gas:

- In the oil and gas industry, industrial seals are used in valves, pumps, and pipelines to prevent leakage and ensure safety.

- Chemical Processing:

- In chemical plants, seals are employed to contain corrosive or toxic substances, preventing leaks that could harm workers or the environment.

- Pharmaceutical and Food Processing:

- Seals used in these industries must meet strict regulatory standards to ensure product purity and consumer safety.

- Marine and Offshore:

- In marine and offshore applications, seals must withstand exposure to saltwater, extreme temperatures, and high pressures.

- HVAC and Refrigeration:

- Industrial seals in HVAC systems help maintain energy efficiency and prevent refrigerant leakage.

- Power Generation:

- In power plants, seals are used in turbines, generators, and pumps to maintain efficiency and prevent leaks.

In conclusion, industrial seals are indispensable components in a wide variety of industries, providing essential functions such as leakage prevention, environmental protection, pressure management, and temperature resistance. The selection of the right type of seal and material depends on the specific application’s requirements, ensuring the efficient and safe operation of industrial equipment and systems. Seals contribute to the longevity and reliability of machinery, reduce maintenance costs, and play a crucial role in safety and environmental protection in various industrial settings.