Concrete pipe seals are specialized components used in the construction and maintenance of concrete pipes. These seals play a crucial role in ensuring the integrity and functionality of concrete pipe systems, which are widely used in various infrastructure applications, including stormwater management, wastewater transport, and drainage systems. Concrete pipe seals are designed to provide secure connections between pipe sections, preventing leaks, infiltration, and exfiltration of water, soil, or contaminants. Here is an overview of concrete pipe seals, their types, functions, and applications:

Types of Concrete Pipe Seals:

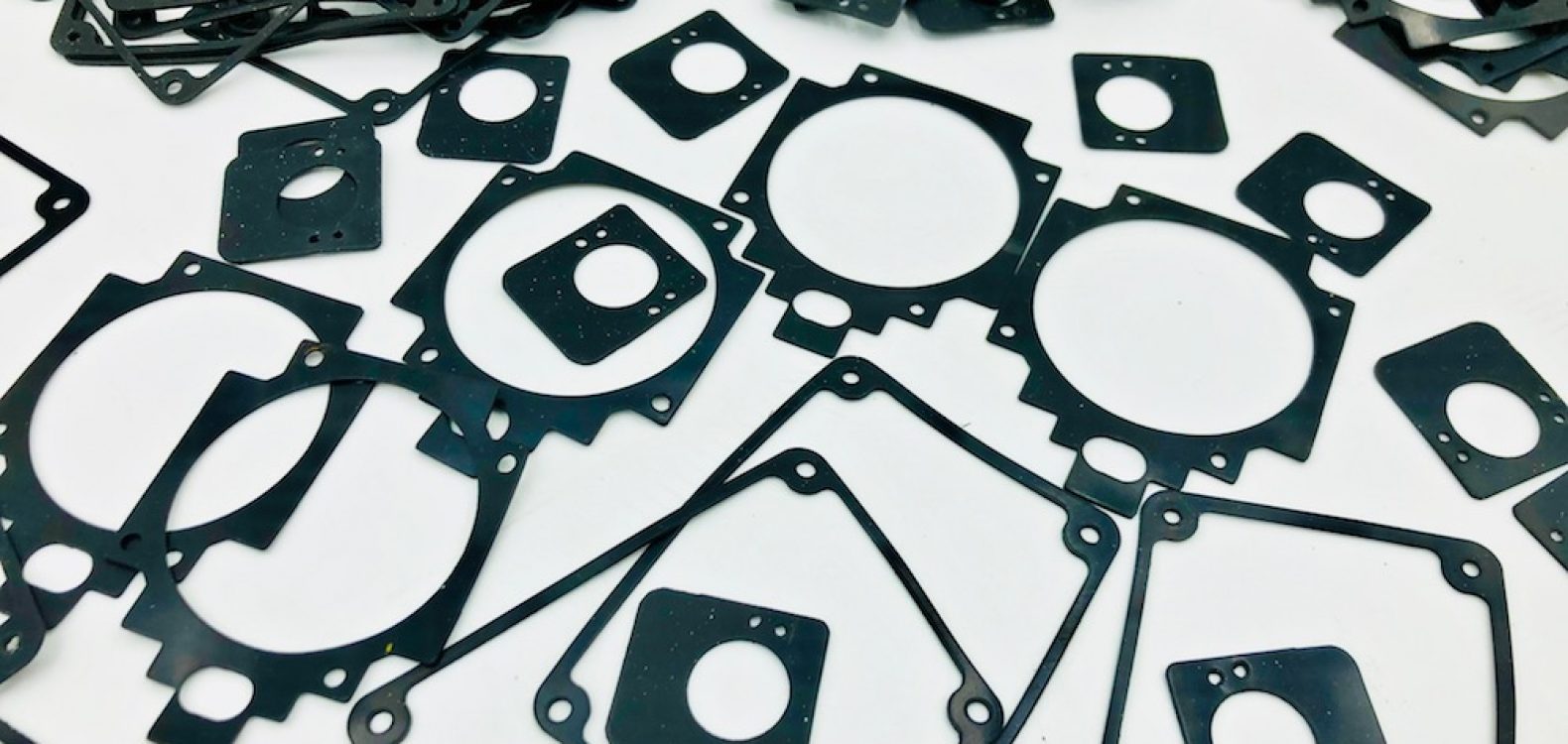

- Gasket Seals: These seals are typically made of rubber or elastomeric materials and are installed in the joint between concrete pipe sections. Gasket seals create a watertight and airtight seal, preventing the escape of liquids or the intrusion of groundwater or soil.

- Mastic Seals: Mastic seals consist of a sealant compound, often asphaltic or butyl-based, applied between the spigot and bell ends of concrete pipes. Mastic seals provide an additional layer of protection against water infiltration and are often used in combination with gasket seals.

- Compression Seals: Compression seals, also known as o-ring seals, are made of elastomeric materials and are placed inside the joint cavity of concrete pipes. When the pipes are joined, the compression seals compress to create a secure and flexible seal.

Functions of Concrete Pipe Seals:

- Watertightness: The primary function of concrete pipe seals is to create watertight seals at the joints of concrete pipes. This prevents the loss of transported fluids, the infiltration of groundwater into wastewater systems, and the exfiltration of wastewater into the surrounding soil.

- Durability: Concrete pipe seals are designed to withstand the rigors of underground or submerged environments. They resist degradation due to exposure to moisture, chemicals, and UV radiation.

- Flexibility: These seals accommodate the natural movement and settling of the soil and concrete pipes, ensuring that the seal remains effective over time.

- Leak Prevention: By creating a secure and reliable connection between concrete pipe sections, these seals minimize the risk of pipe leaks, which can lead to structural damage and environmental contamination.

Applications of Concrete Pipe Seals:

Concrete pipe seals are used in a wide range of applications, including:

- Stormwater Management: They are employed in stormwater drainage systems to prevent rainwater from infiltrating the ground and to efficiently transport stormwater to designated outlets.

- Wastewater Transport: In wastewater collection and conveyance systems, concrete pipe seals maintain the integrity of the pipes, preventing sewage from escaping into the environment.

- Culvert Systems: Concrete pipe seals are used in culvert systems to facilitate the passage of water under roads, railways, and embankments while preventing soil erosion.

- Irrigation and Water Supply: These seals are used in irrigation systems and water supply networks to maintain the integrity of pipelines and prevent water loss.

- Utilities and Infrastructure: They play a vital role in various infrastructure projects, including tunnels, bridges, and underground utilities.

In summary, concrete pipe seals are essential components of concrete pipe systems, ensuring the durability, integrity, and functionality of these systems in critical infrastructure applications. The selection of the appropriate seal type and installation methods should align with the specific requirements of the project and the type of concrete pipes being used. Properly installed and maintained concrete pipe seals contribute to the efficient and reliable operation of drainage and wastewater systems while protecting the environment from potential contaminants.