EPDM rubber seals and gaskets are widely used in various industries for their excellent properties. Here’s a breakdown:

- Material Composition: EPDM rubber is a synthetic elastomer composed primarily of ethylene and propylene, with a small amount of diene monomer. This composition gives EPDM its exceptional resistance to heat, weathering, ozone, and UV radiation.

- Weather Resistance: EPDM rubber is highly resistant to weathering, making it suitable for outdoor applications. It can withstand extreme temperatures, from -40°C to 120°C, without significant degradation, making it ideal for automotive, construction, and outdoor sealing applications.

- Chemical Resistance: EPDM exhibits good resistance to a wide range of chemicals, including acids, alkalis, and polar solvents. This chemical resistance makes it suitable for use in environments where exposure to various substances is expected.

- Water and Steam Resistance: EPDM gaskets has excellent water and steam resistance properties, making it commonly used in plumbing, HVAC, and automotive sealing applications.

- Electrical Insulation: EPDM rubber has good electrical insulation properties, making it suitable for use in electrical enclosures, gaskets, and seals where electrical conductivity needs to be avoided.

- Flexibility and Elasticity: EPDM rubber is highly flexible and elastic, allowing it to conform to irregular surfaces and maintain a tight seal over time, even with repeated compression and expansion cycles.

- Low-Temperature Flexibility: EPDM rubber retains its flexibility even at low temperatures, which is crucial for applications where sealing performance is required in cold environments.

- Longevity and Durability: EPDM rubber is known for its longevity and durability. It has a relatively long service life compared to other elastomers, making it a cost-effective choice for many sealing applications.

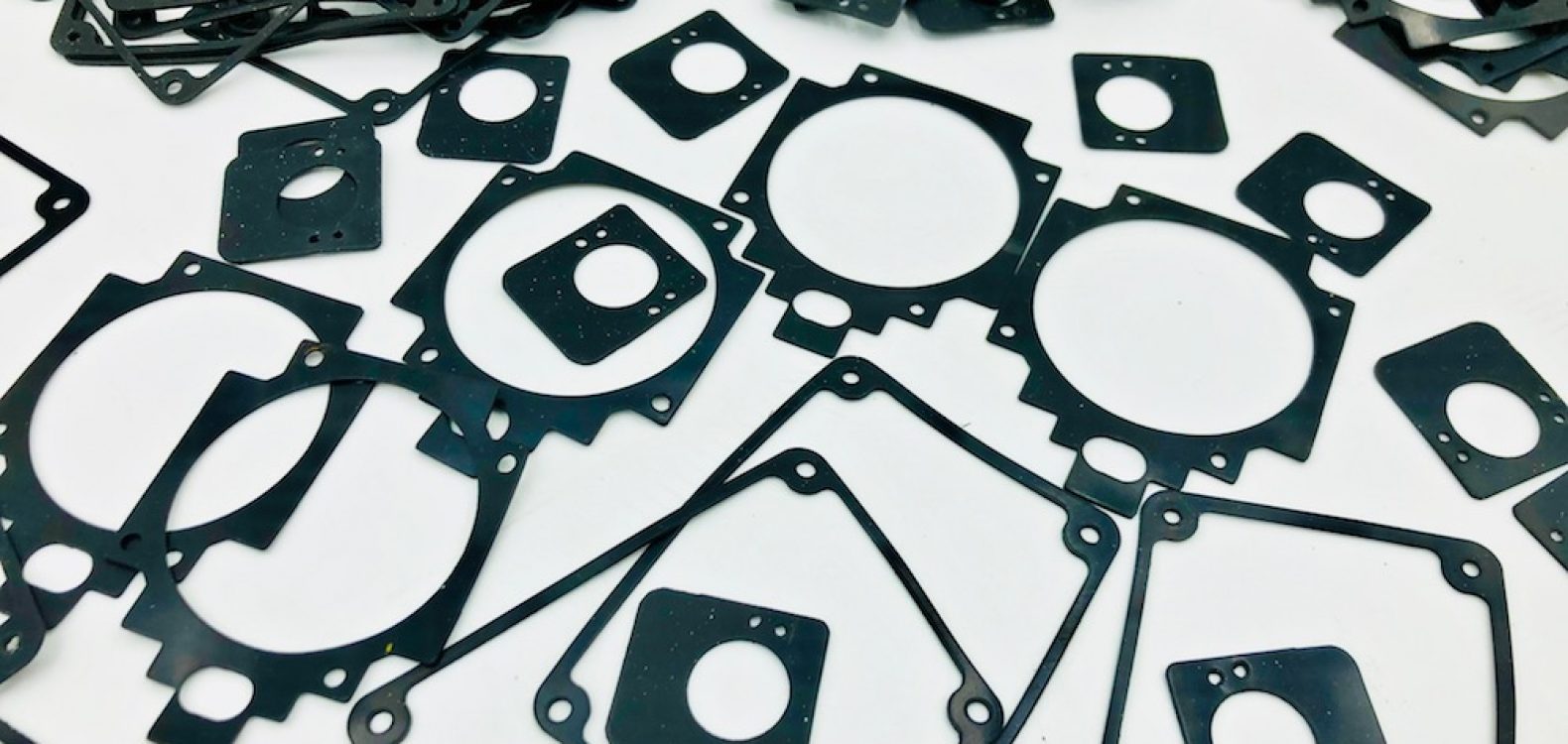

- Manufacturing Processes: EPDM rubber seals and gaskets can be manufactured using various processes, including extrusion, molding, and die-cutting, allowing for customization to meet specific application requirements.

EPDM rubber seals and gaskets offer a combination of excellent properties that make them suitable for a wide range of applications across industries, including automotive, construction, aerospace, and industrial machinery.