Dilatation seals, also known as expansion joints or expansion seals, are crucial components used in various engineering and construction applications to address the challenges posed by the expansion and contraction of materials due to temperature fluctuations, mechanical stress, and other environmental factors. These seals play a vital role in maintaining the integrity and longevity of structures and systems, ensuring safety and functionality.

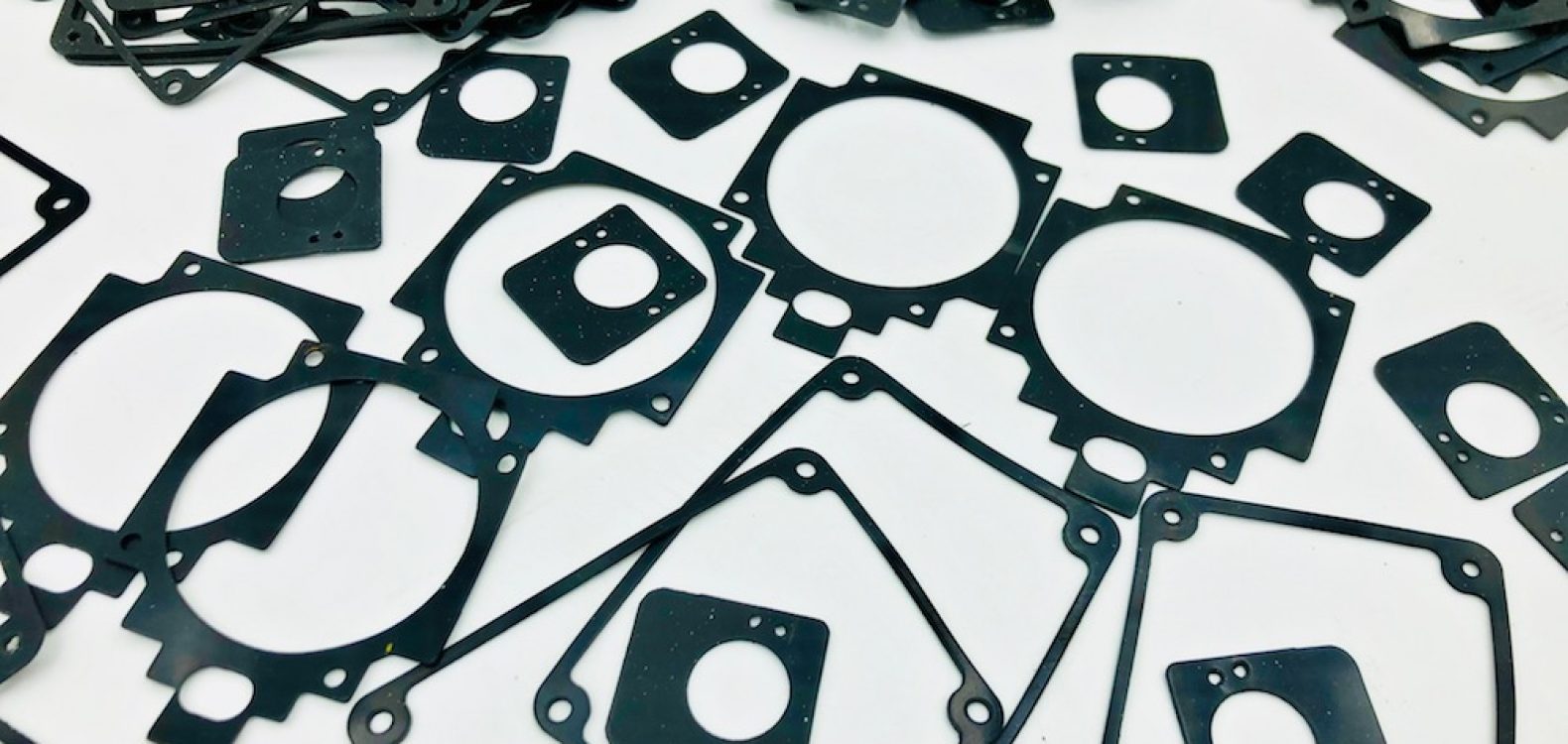

A dilatation seal typically consists of a flexible or compressible material placed within or between adjacent structural elements to accommodate movement while preventing the ingress of moisture, debris, and other potentially damaging elements. These seals come in a wide variety of designs and materials to suit different applications, and they are used in a range of industries, including construction, civil engineering, aerospace, automotive, and manufacturing.

The primary functions and characteristics of dilatation seals include:

- Compensating for Thermal Expansion and Contraction: One of the most common reasons for using dilatation seals is to manage the expansion and contraction of materials caused by temperature variations. For instance, in bridges, buildings, and pipelines, temperature fluctuations can cause the materials to expand during hot weather and contract in cold conditions. Dilatation seals allow these structures to flex without causing damage.

- Absorbing Structural Movements: Beyond thermal expansion, structures can experience various forms of movement, such as settlement, vibrations, or seismic activity. Dilatation seals provide flexibility to accommodate these movements, reducing the risk of structural damage and maintaining safety.

- Preventing Water Ingress: Dilatation seals are designed to create a barrier against moisture infiltration. This is essential in applications like building facades, underground tunnels, and infrastructure subjected to rain, snow, or groundwater.

- Enhancing Durability: By reducing the impact of stress and strain, dilatation seals help extend the lifespan of structural elements and components. They prevent cracks, fractures, and wear and tear due to mechanical forces.

- Noise and Vibration Dampening: In transportation systems, particularly railways and roadways, dilatation seals can absorb vibrations and reduce noise generated by moving vehicles, improving the comfort and safety of passengers.

- Seismic Isolation: In areas prone to earthquakes, dilatation seals can be employed to separate adjoining structures, allowing them to move independently and reducing the transmission of seismic forces.

- Aesthetic Considerations: In architectural applications, dilatation seals can be designed to blend seamlessly with the appearance of the structure, maintaining a clean and attractive aesthetic while providing functionality.

Materials used for dilatation seals include rubber, silicone, metal, fabric-reinforced elastomers, and thermoplastics. The choice of material depends on the specific application, environmental conditions, and required performance characteristics.

Dilatation seals come in various forms, including expansion joints for bridges, architectural expansion joints, pipeline expansion joints, and industrial expansion joints, each tailored to meet the unique requirements of their respective applications.

In summary, dilatation seals are essential components that facilitate the movement and flexibility of structures and systems while safeguarding against the detrimental effects of expansion, contraction, and environmental factors. Their design, material, and installation are critical factors in ensuring the integrity, safety, and longevity of various engineering and construction projects.