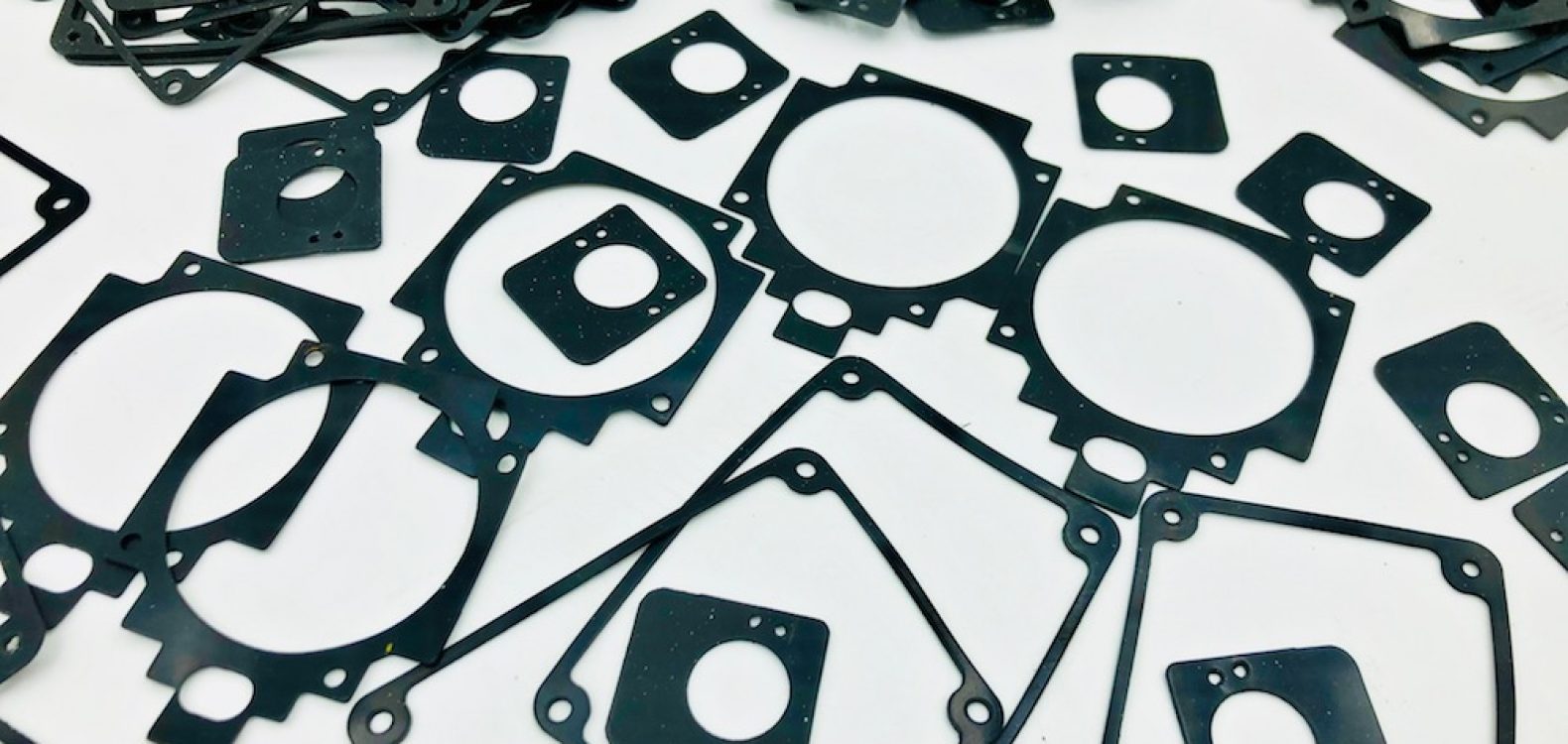

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are widely used in various industries and applications due to their excellent properties and versatility. EPDM is a synthetic rubber known for its outstanding weather resistance, chemical resistance, and durability, making it a preferred choice for gaskets in a wide range of environments. Here’s a detailed overview of EPDM rubber gaskets:

Key Features of EPDM Rubber Gaskets:

- Weather Resistance: EPDM rubber gaskets are highly resistant to weathering, UV radiation, and ozone exposure, making them suitable for outdoor and long-term applications. They can withstand extreme temperature variations without deteriorating.

- Chemical Resistance: EPDM gaskets exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oxidizing agents. This chemical resistance is valuable in various industrial settings.

- Waterproofing: EPDM rubber is inherently waterproof, making it ideal for sealing applications where preventing the ingress of water or moisture is essential.

- Flexibility: EPDM rubber is highly flexible and elastic, allowing it to conform to irregular surfaces and maintain a reliable seal, even under varying pressures or movements.

- Tensile Strength: EPDM rubber has good tensile strength and tear resistance, ensuring that gaskets remain intact and functional under mechanical stress.

- Electrical Insulation: EPDM is an excellent electrical insulator, making it suitable for use in electrical enclosures, panels, and other applications where electrical isolation is necessary.

Applications of EPDM Rubber Gaskets:

EPDM rubber gaskets are used in a wide range of industries and applications, including:

- Automotive: EPDM gaskets are commonly used in automotive engines, cooling systems, and weatherstripping due to their heat resistance and durability.

- Construction: They are used in construction materials such as window seals, roofing, and expansion joint seals to provide weatherproofing and durability.

- HVAC Systems: EPDM gaskets are used in heating, ventilation, and air conditioning systems to create airtight and watertight seals.

- Plumbing: EPDM gaskets are employed in plumbing fixtures and connectors to prevent leaks in water and gas distribution systems.

- Electronics: They are used as gaskets and seals in electronic enclosures and control panels to protect sensitive equipment from dust, moisture, and contaminants.

- Marine Industry: EPDM gaskets are suitable for marine applications, including sealing hatches, windows, and other openings on boats and ships.

- Chemical Processing: EPDM gaskets are used in chemical processing equipment and pipelines due to their chemical resistance.

- Food and Beverage Industry: EPDM gaskets are used in food and beverage processing equipment, providing a safe and hygienic sealing solution.

Manufacturing Processes:

EPDM rubber gaskets are typically manufactured using methods such as compression molding, injection molding, or extrusion, depending on the specific shape and requirements of the gasket. The material is first mixed with curing agents, additives, and fillers to achieve the desired properties. Then, it is processed and shaped into the final gasket form, followed by curing to set the rubber.

In summary, EPDM rubber gaskets are versatile sealing solutions known for their exceptional weather resistance, chemical resistance, and flexibility. They are used in a wide range of industries and applications where reliable sealing, durability, and environmental resistance are essential. EPDM gaskets contribute to the efficiency, safety, and longevity of various systems and components.